Markets

Mining

Down The Hole Bits, Drill Bits

Wear protection of buttons and extended life of the drill bit, by hardfacing Tungsten Carbide

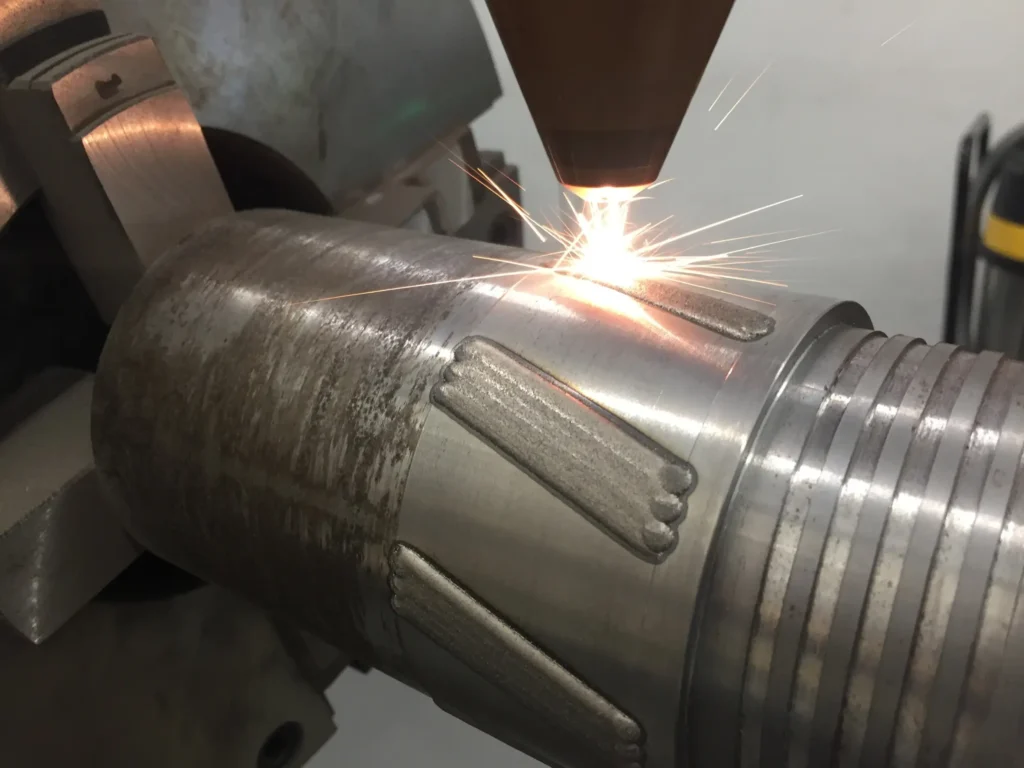

Hammer Case, Drive Subs

Protection of the hammer case by wear protection layers of Tungsten Carbide

Legs for tricone bits

Tungsten Carbide Hardfacing, precise and consistent unlike TIG and manual welding methods

Cones of tricone bits

Hardfacing of Tungsten Carbide without spillage and overspray over to the TCI buttons

Reamer shells

Deposition of Tungsten Carbide as a replacement of sintering polycrystalline diamonds

Automotive

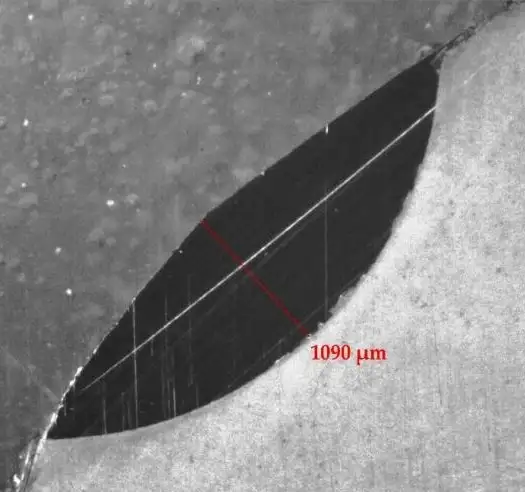

Engine Valve Seat hardfacing / deposit

Laser deposition of seats for engine valves enables high productivity and near zero quality defects. Materials:

- Stellites © : Grade 6, Grade 12, Grade F, Grade 21

- Inconel 625

- Triballoy 400

- Eatonite 6

Engine Valve Tipping

with Stellite

Laser DED as a technology to deposit Stellite on the tip of the engine valves, instead of hardening

Process Industry

Ball valves

Plug valves

Segmented Balls

Heavy Industry

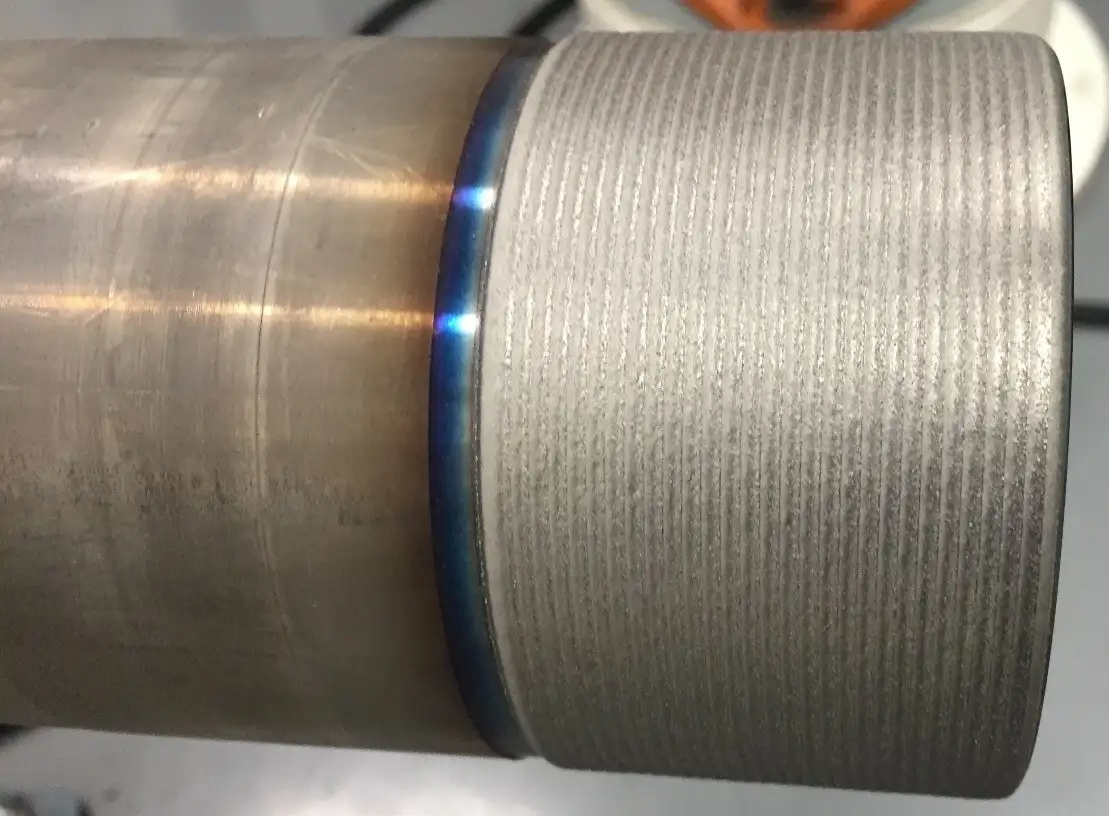

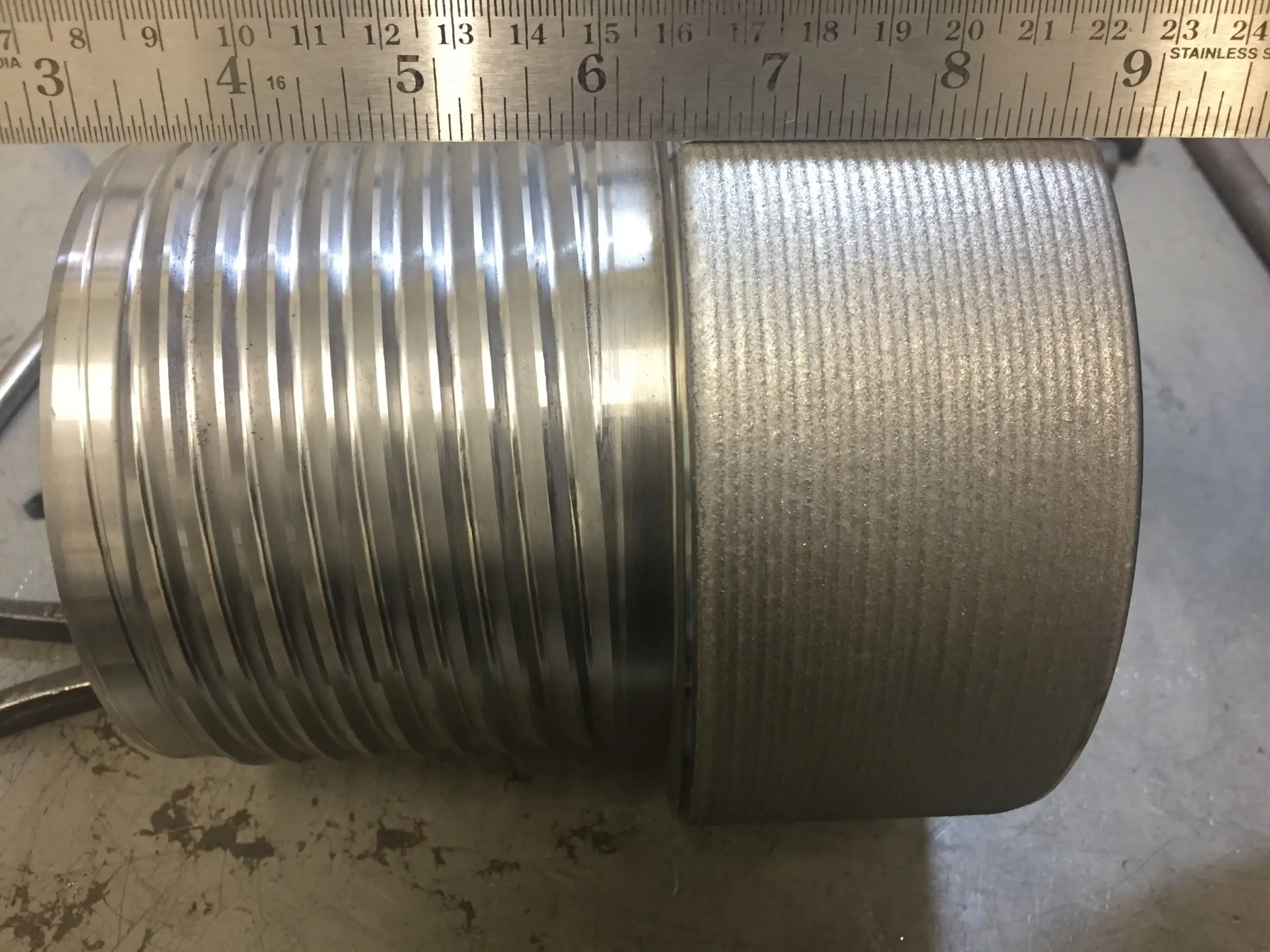

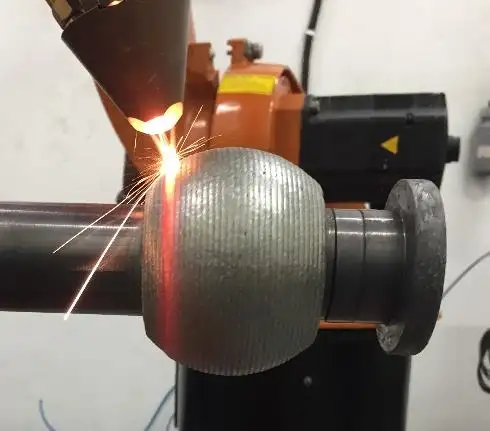

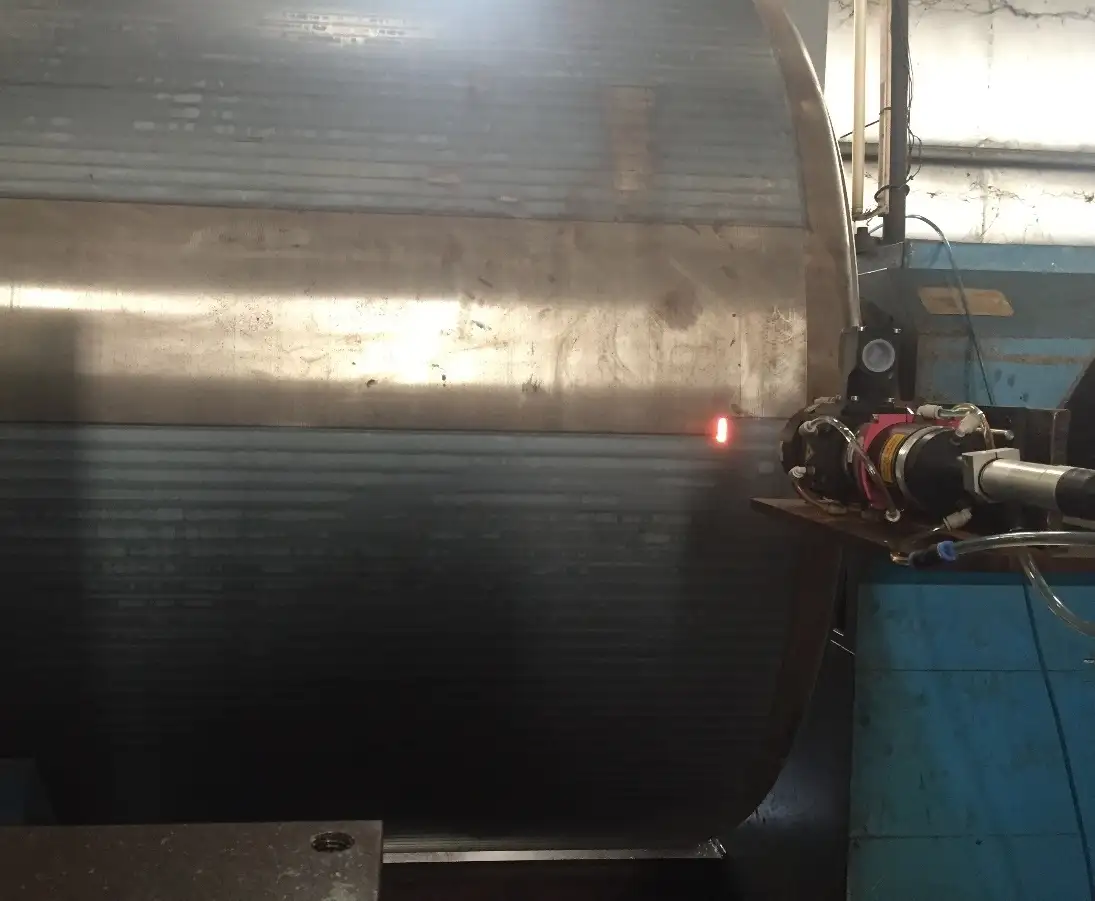

Refurbishment of shafts

- Rebuild of bearing areas

- Rebuild of key way areas

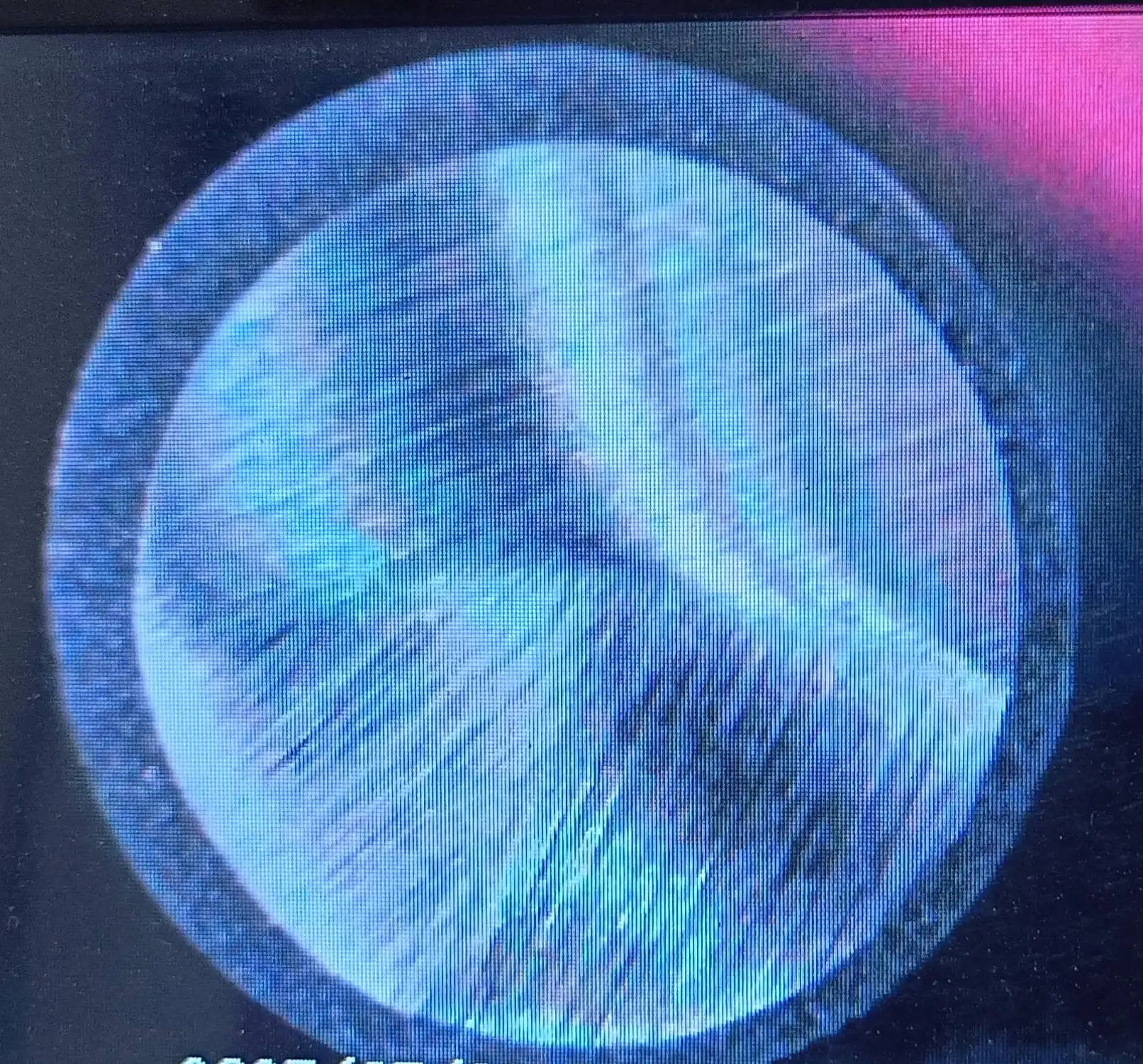

Laser Hardening

Our laser hardening and repair solutions tackle the toughest challenges in heavy engineering. From hardening 80-ton shafts to restoring critical components, we ensure durability and precision for large-scale industrial applications.

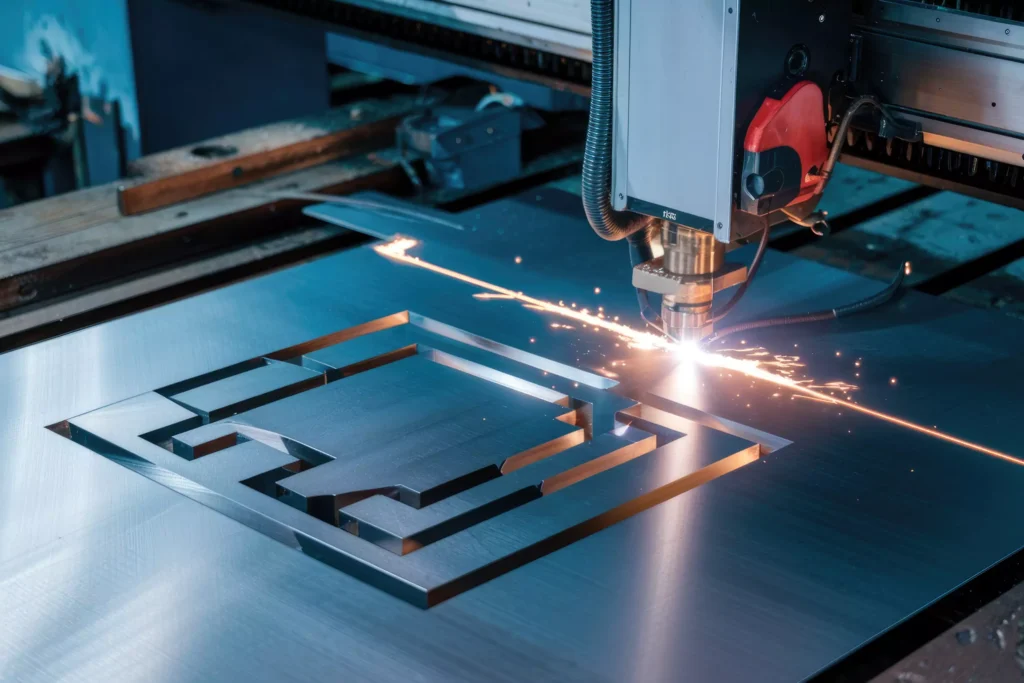

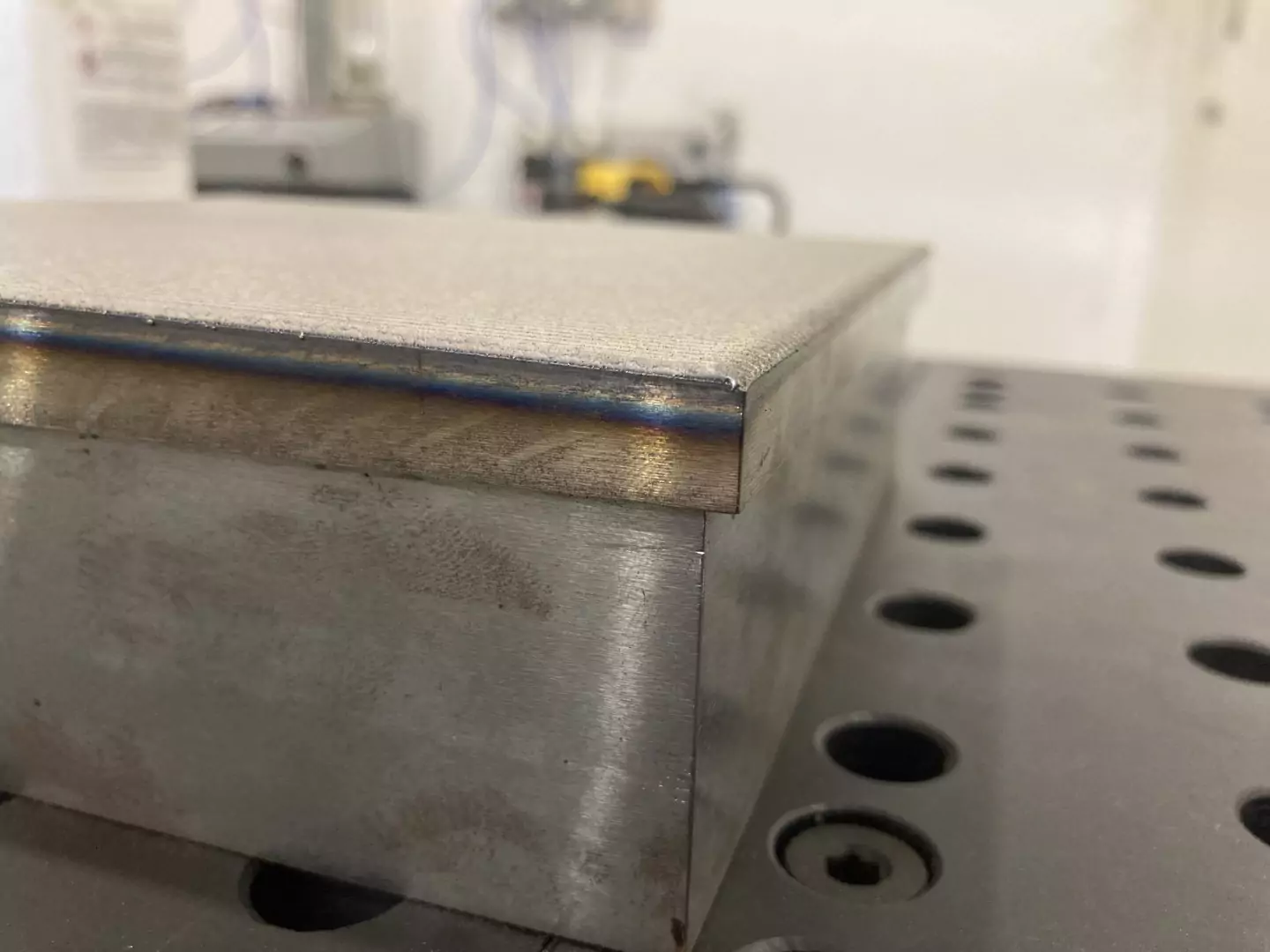

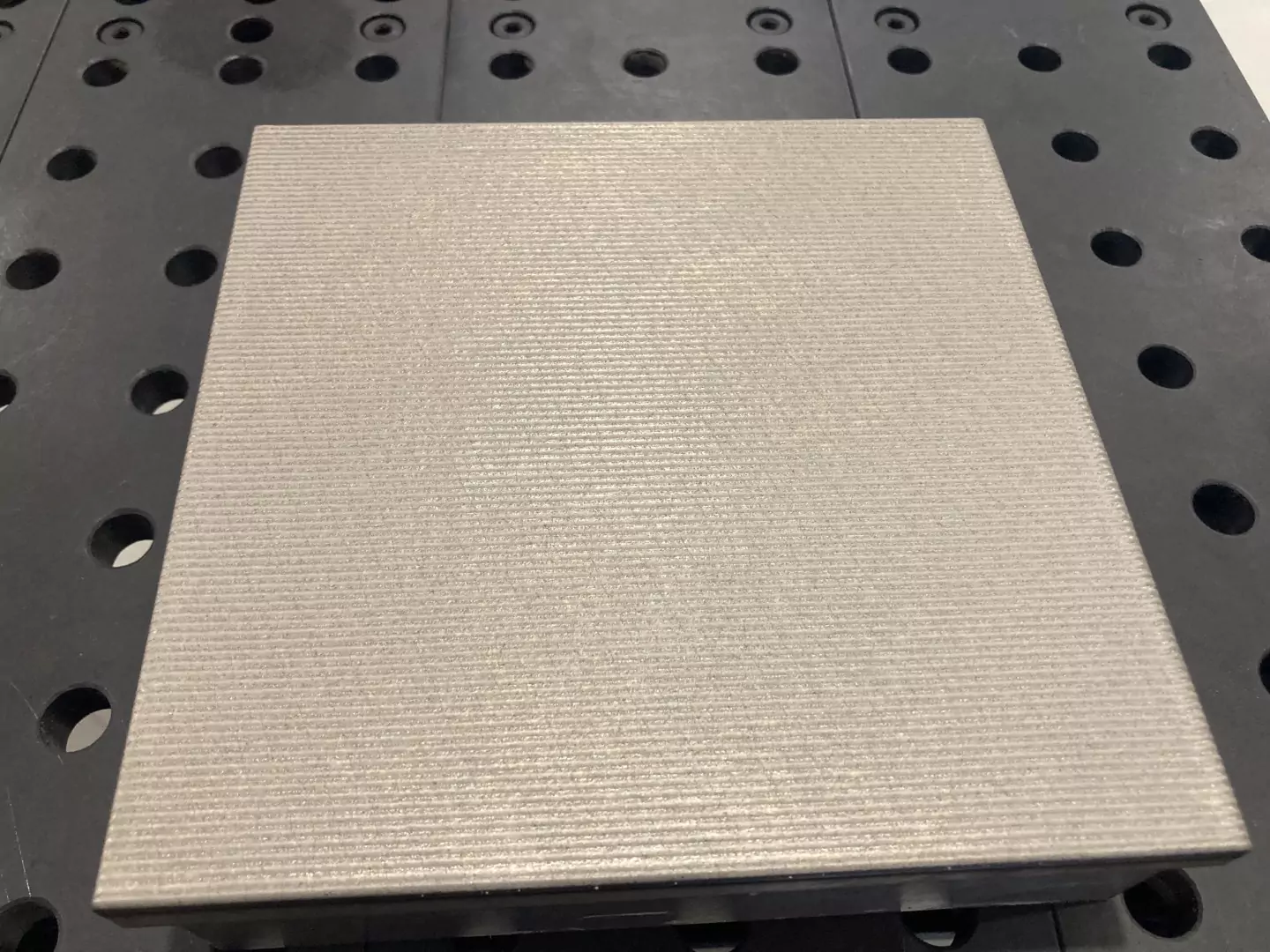

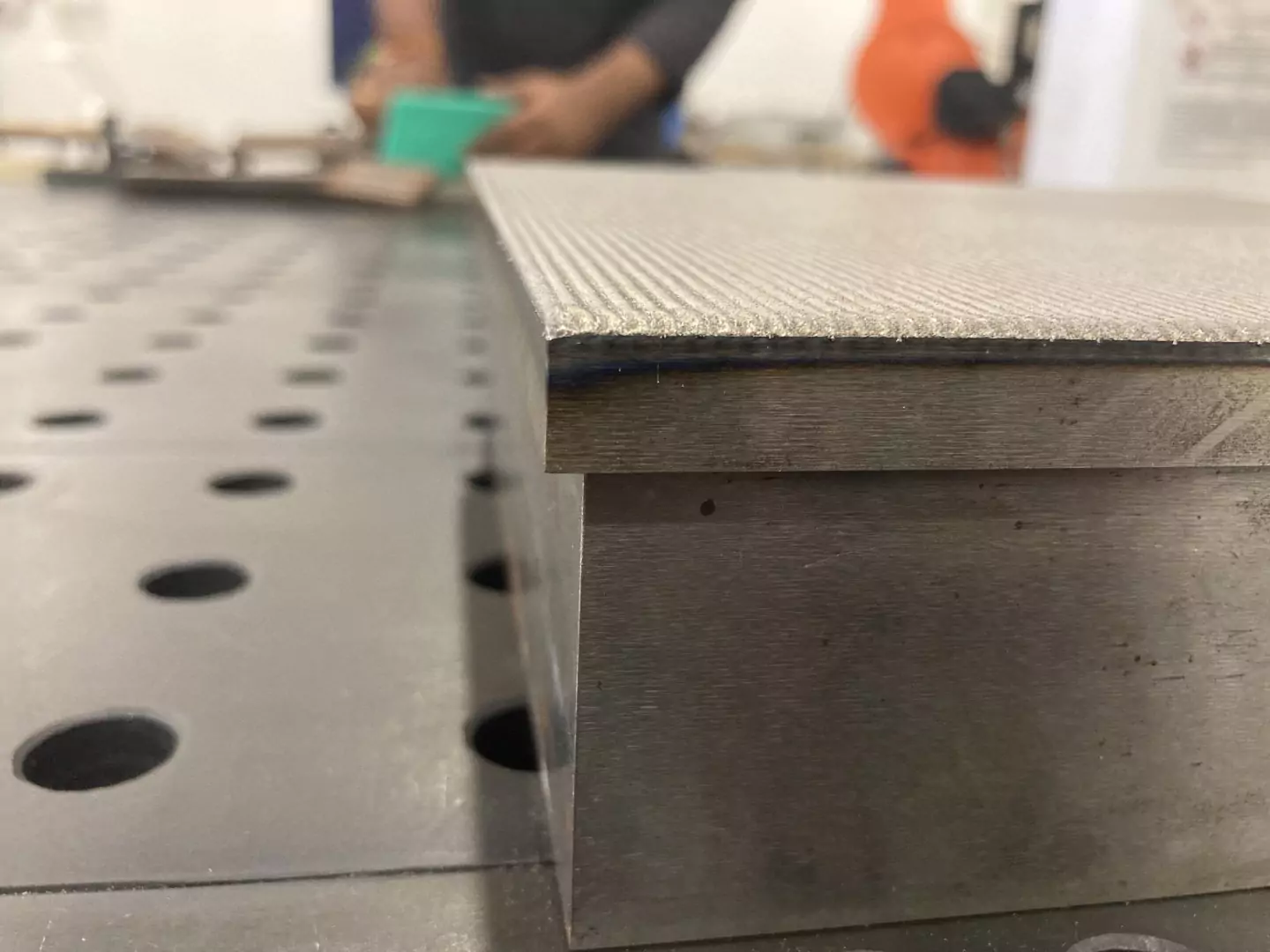

Tools & Dies

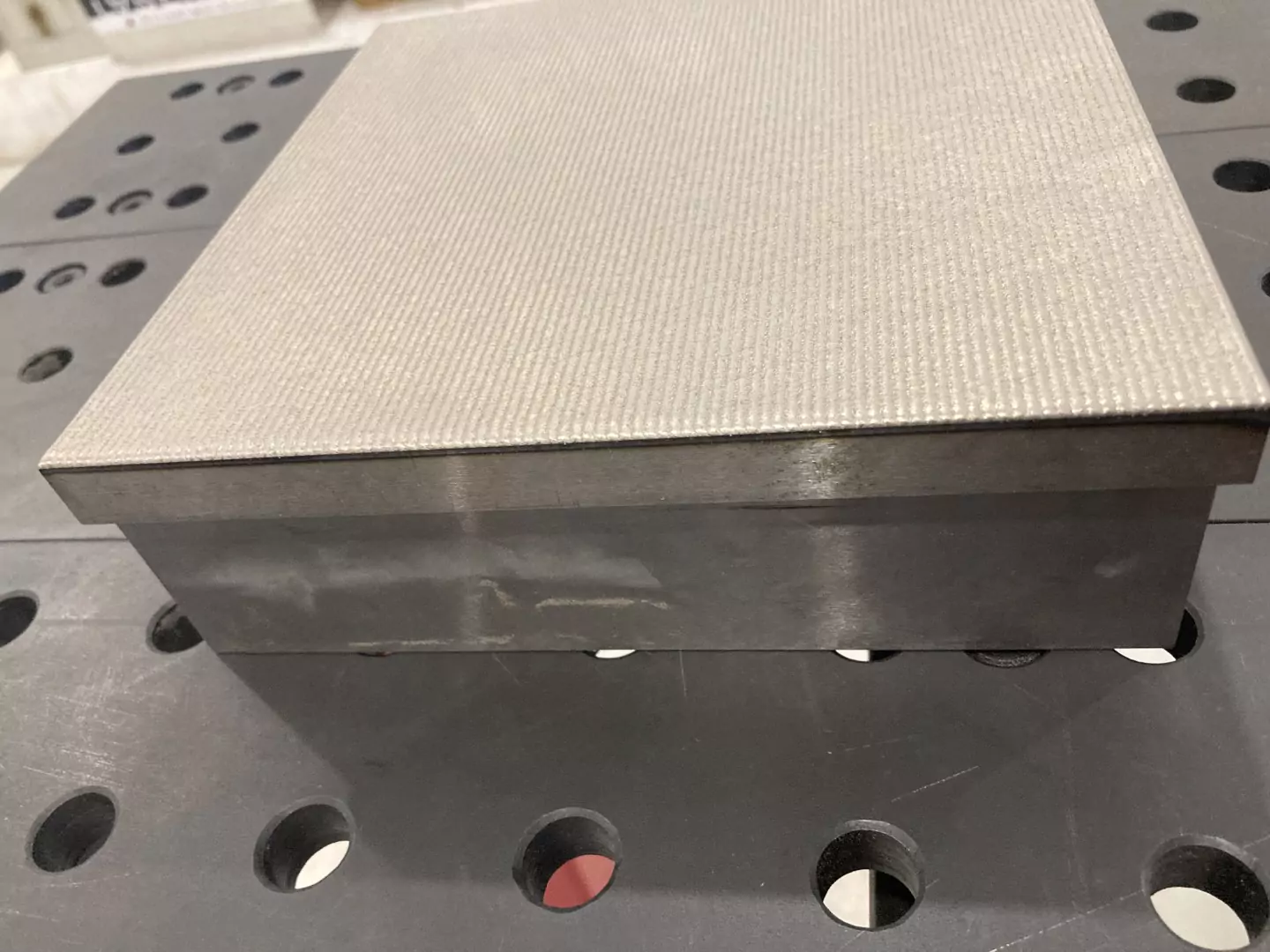

Tungsten Carbide deposit

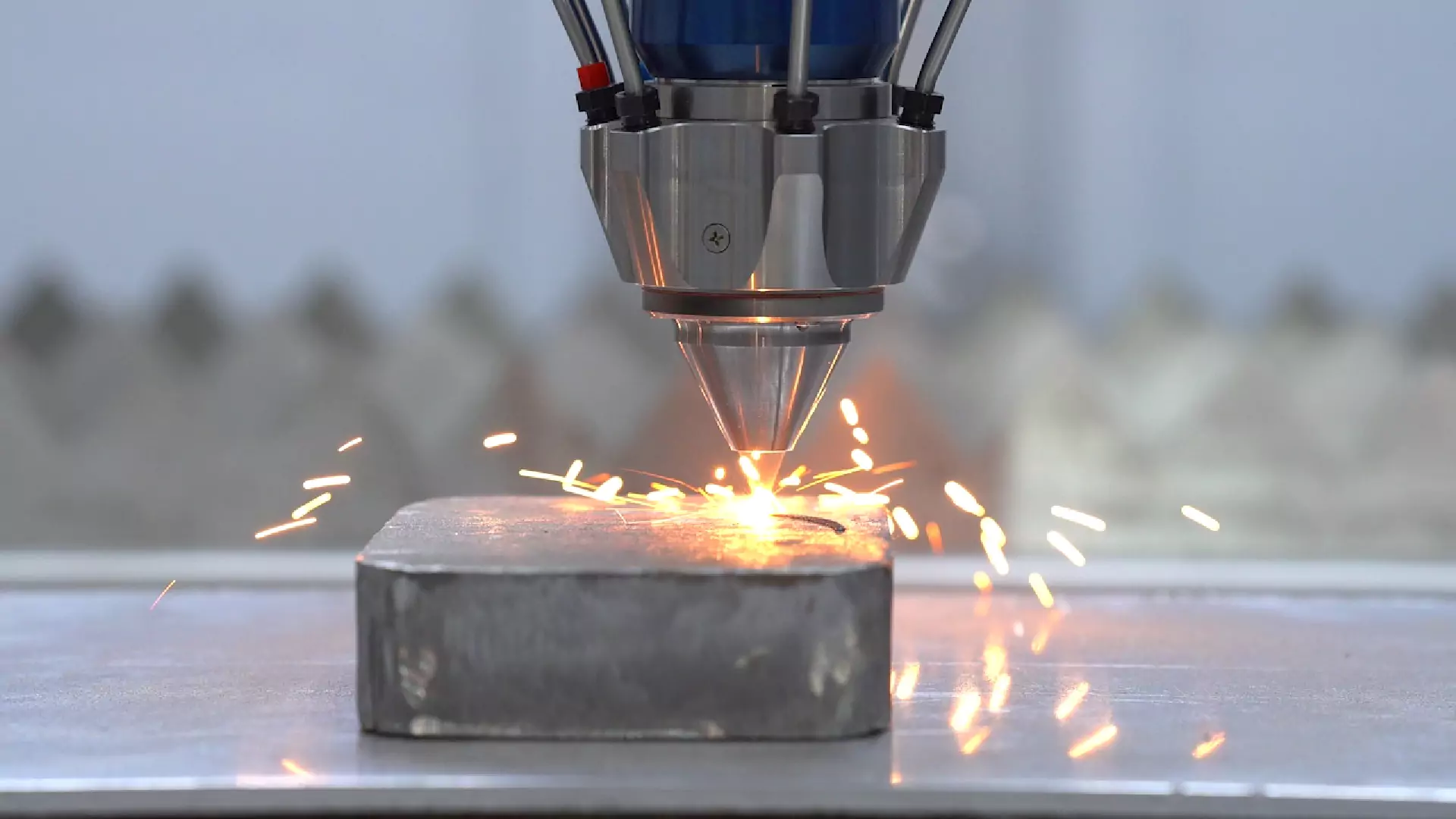

Additive Manufacturing

Laser powder DED additive manufacturing